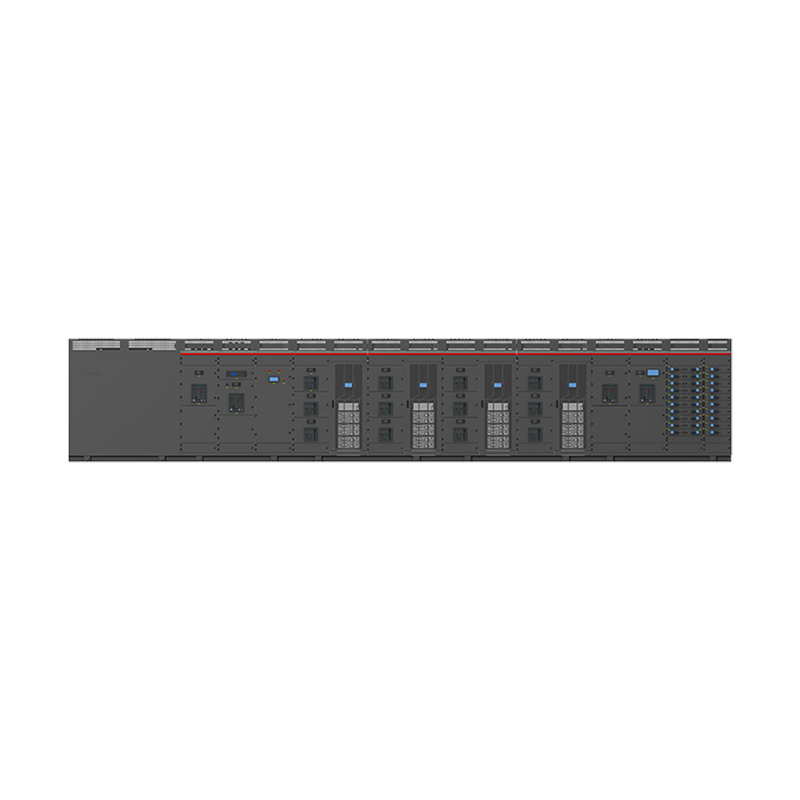

A busway or bus duct is a power distribution device used for centralized allocation of electrical energy. It consists of a metal enclosure, conductive bars (busbars), and insulation materials. This equipment is primarily used to replace traditional cables, providing efficient and flexible power transmission and distribution, especially suited for high-current and high-power applications.

Key Components and Features of a busway or bus duct:

Metal Enclosure: Provides physical protection and structural integrity, shielding the internal components from environmental factors and mechanical damage.

Conductive Bars (Busbars): Typically made of copper or aluminum, these bars are the main conductive elements responsible for carrying high electrical currents.

Insulation Materials: Surround the busbars to prevent electrical shorts and ensure safe operation by insulating the conductive parts from each other and the metal housing.

Here are several advantages and disadvantages of busway:

Advantages:

High Current-Carrying Capacity:

Suitable for high-current applications due to its robust design and use of conductive materials like copper or aluminum.

Flexible Installation:

Easy to install, expand, and modify, making it ideal for environments where changes may be frequent or where future expansions are anticipated.

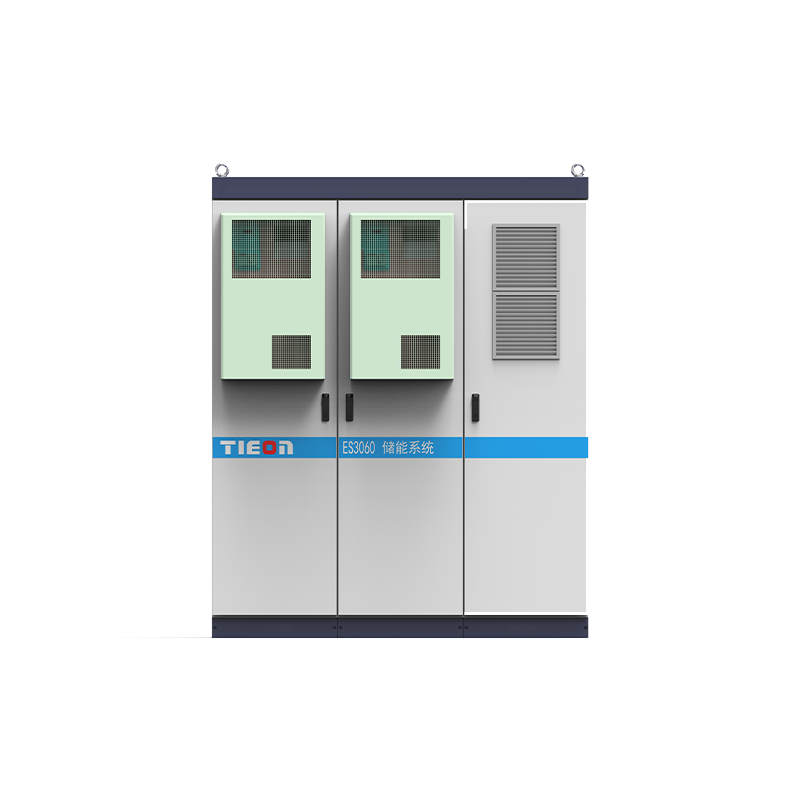

Excellent Heat Dissipation:

Superior thermal performance ensures stable operation by effectively dissipating heat generated during power transmission.

Space-Saving Design:

Compact and organized, busways help save space compared to traditional cable systems, contributing to a cleaner and more aesthetically pleasing installation.

Disadvantages:

Higher Initial Investment:

The upfront cost of purchasing and installing busways is generally higher than that of traditional cables.

High Precision Installation Requirements:

Proper installation requires precise alignment and secure connections, which can be more demanding compared to simpler cable installations.

Special Protection Needed in Harsh Environments:

In damp or corrosive environments, additional protective measures are necessary to prevent damage to the busway components, adding complexity and potentially increasing costs.

Here are the applications of the busway :

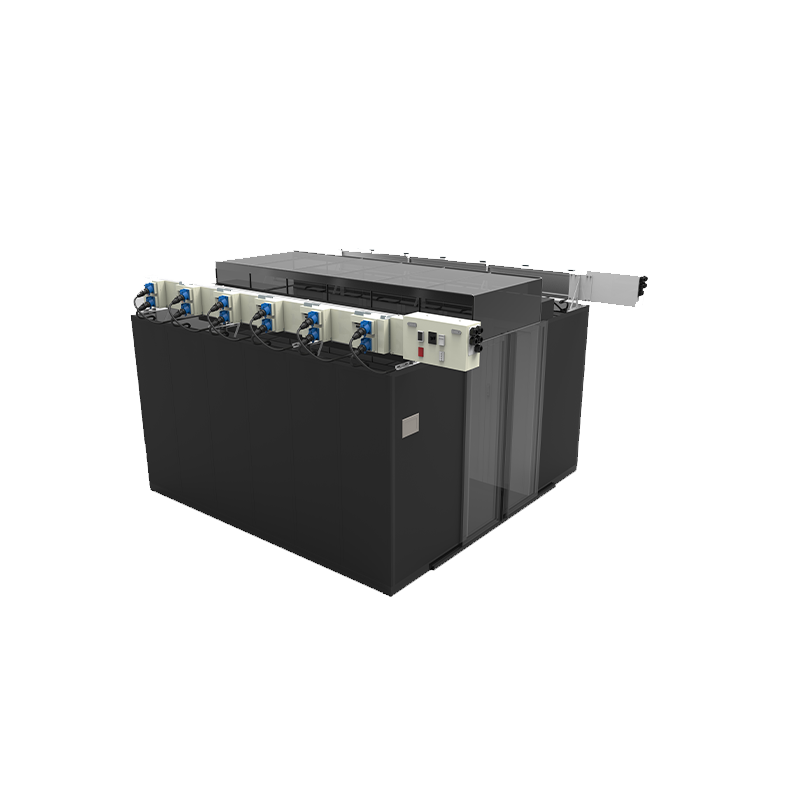

Industrial Facilities: Used in large manufacturing plants and factories where high-capacity power distribution is essential.

Commercial Buildings: Installed in office buildings, shopping malls, and other commercial spaces to manage extensive electrical loads efficiently.

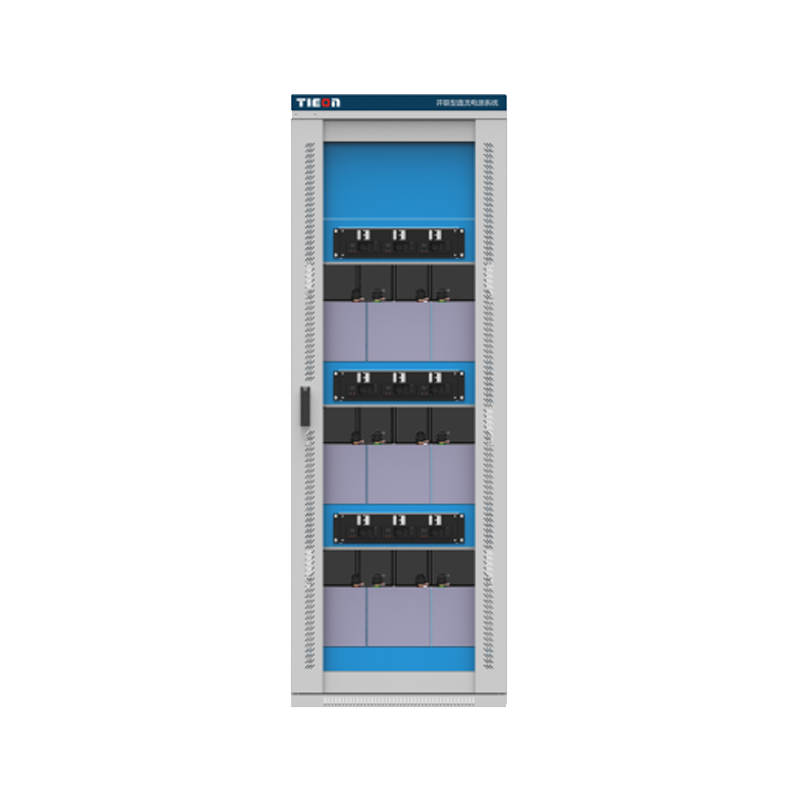

Data Centers: Critical for providing reliable power distribution to servers and IT infrastructure.

Infrastructure Projects: Utilized in public utilities like substations and transportation systems where high-power and high-reliability requirements exist.

The use of busways or bus ducts enhances the efficiency and reliability of electrical power distribution systems, offering a superior alternative to conventional cabling methods, particularly in high-demand scenarios.

In summary, the busways offer significant advantages in terms of current-carrying capacity, installation flexibility, heat dissipation, and space efficiency. However, they also come with drawbacks such as higher initial costs, stringent installation requirements, and the need for special protection in challenging environments. Understanding these pros and cons can help in making informed decisions about when and where to use busways in electrical power distribution systems.