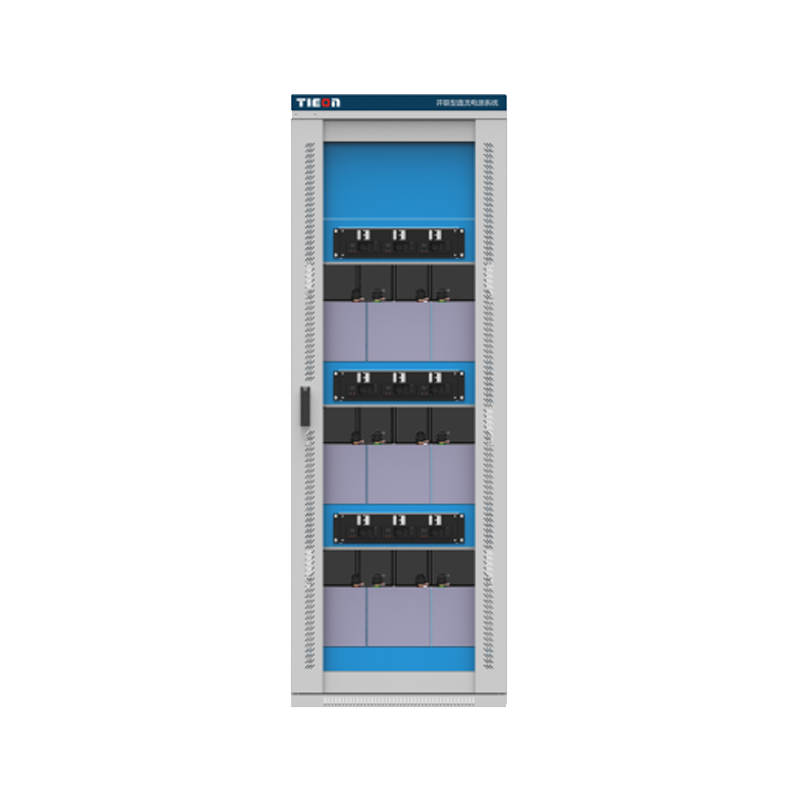

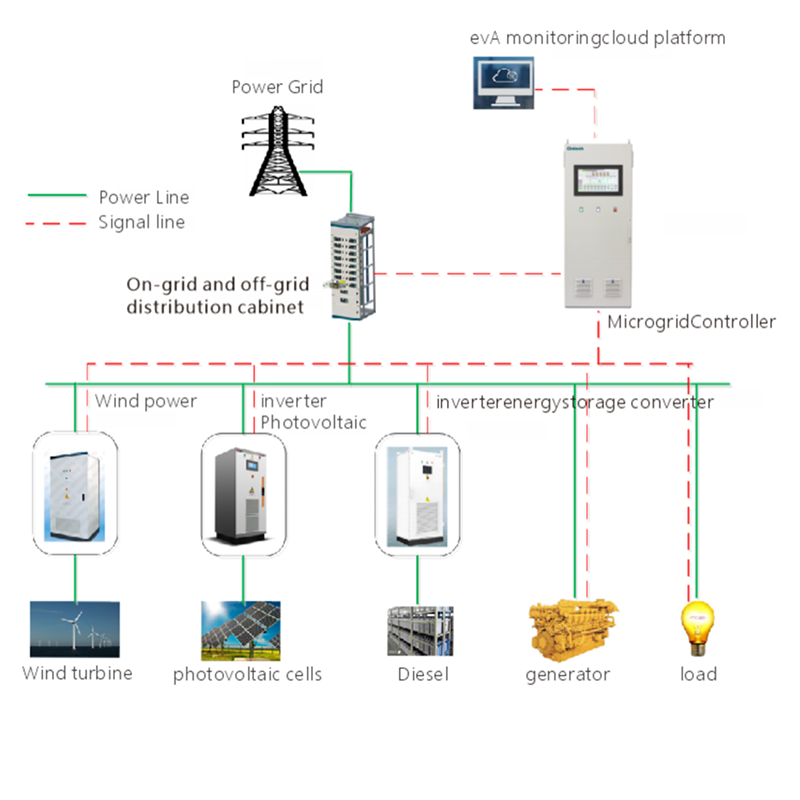

SPC2.0 LV Cabinet

SPC2.0 LV Cabinet is designed with standard modularization, using insulation fastening technology for connections. It relies on eVA intelligent distribution cloud monitoring to achieve real-time detection of feeder circuit temperatures, enabling fully wireless collection of all electricity usage data. This system is secure and reliable, effectively enhancing electrical efficiency, saving equipment energy consumption, and reducing carbon emissions.

Share to:

SMART

- Intelligent cloud platform management: Monitor currents, voltages, power, energy consumption, harmonics, temperatures, switch statuses, and other parameters around the clock.

- Remote control and adjustment: Automatically send fault warnings and real-time alerts to computers or smartphones, supporting remote control and adjustment.

SAFE

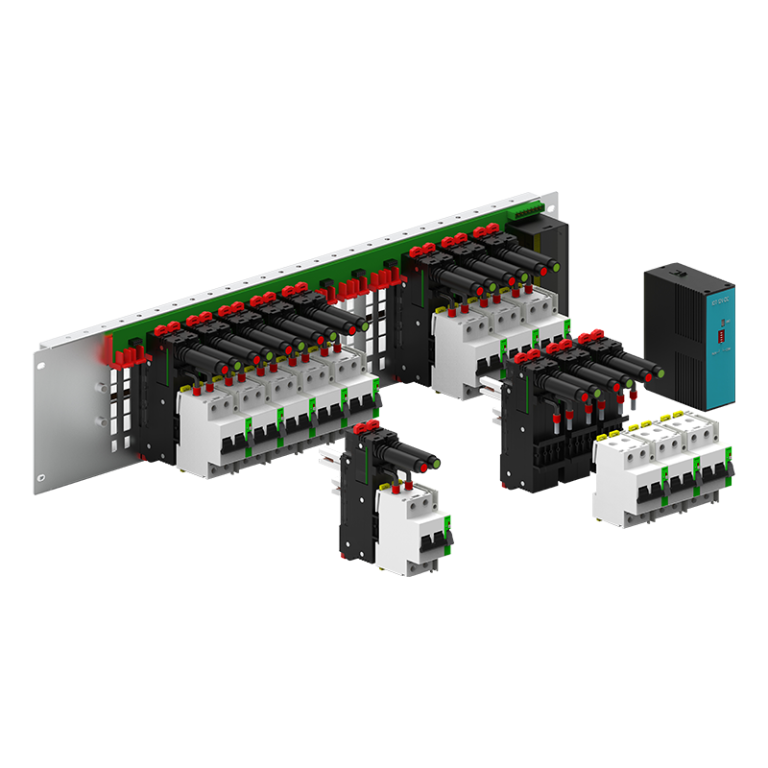

- Insulation fastening technology: Utilizes insulation screws for permanent connections, enabling plug-and-play maintenance, ensuring high dynamic and thermal stability, and providing reliable safety.

- Circuit temperature monitoring: Embeds temperature sensors to monitor feeder circuit temperatures in real-time, sending alerts for abnormal temperatures to prevent potential issues.

SIMPLE

- Modular design: The feeder unit consists of standard modules integrating sensing and display functions. It includes two specifications: up to 250A and up to 630A, compatible with mainstream international and domestic switch brands, achieving standardized design.

- Wireless data collection: Utilizes electronic application technology to achieve wireless data collection of temperatures and full electricity usage. It also features complete interfaces for switch status, fire alarms, and other functions.

SAVING

- Assembly line production: Feeder modules are produced on a unified assembly line to ensure product quality.

- Modular assembly: Feeder cabinets are manufactured using modular assembly methods, improving efficiency of system integration and reducing delivery times.

SPEED

- Energy-saving equipment: Through infrared sensing design, control the illumination and shutdown of display systems to save electricity and extend the lifespan of the display system.

|

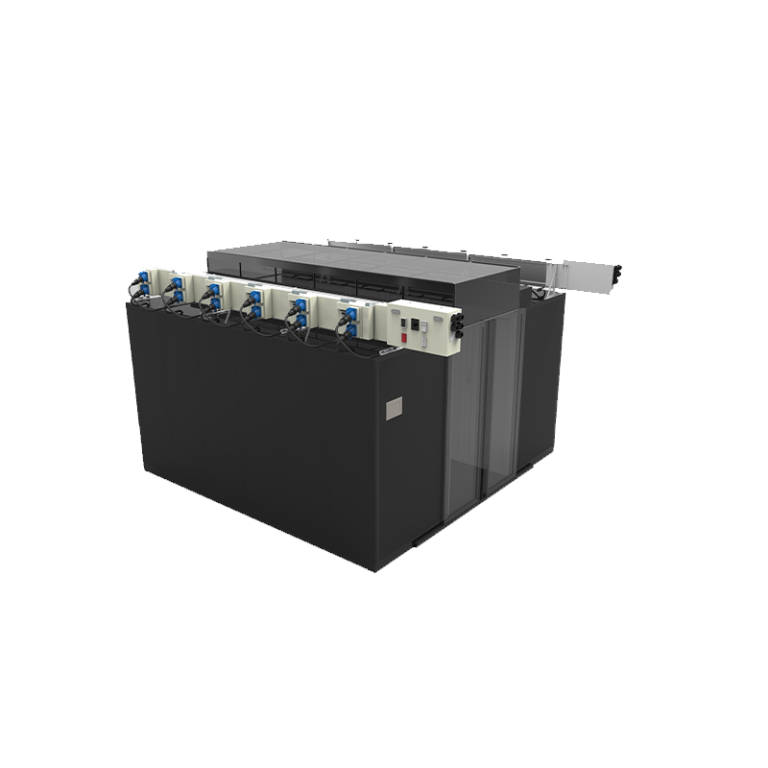

Mechanical data |

Cabinet dimensions |

Width (mm) | 500/600/700/800/1000/1200 | |

| Depth (mm) | 600/800/1000/1200 | |||

| Height (mm) | 2200 | |||

| Inlet/outlet method | Top and bottom inlet/outlet | |||

| Protection level | IP42 | |||

| Module(E) | E=25mm | |||

| Weight | 500kg (according to specifications) | |||

| Casing | Epoxy resin powder coating | |||

| Casing color | 645C、171C (customizable) | |||

|

Electrical data |

Rated operating voltage Ue (V) | 400V/230V AC | ||

| Rated insulation voltage Ui (V) | 690 | |||

| Rated frequency (F) | 50/60Hz | |||

| Impulse withstand voltage (Uimp) | 8kV | |||

| Insulation voltage of auxiliary circuits | 500V AC | |||

| Overvoltage category | IV | |||

| Pollution degree | 3 | |||

| Horizontal busbar | Rated current (Ie) | ≤ 6300A | ||

| Rated short-time withstand current (Icw) | ≤ 105kA | |||

| Vertical busbar | Rated current (Ie) | ≤ 4000A | ||

| Rated short-time withstand current (Icw) | 65kA | |||

| Internal arc human protection IEC 61641 | 85kA 0.3s | |||

| Grounding system | TT, IT, TN-C, TN-S | |||

| Load type | Distribution load,motor load | |||

|

Environment-al data |

Environmental temperature | -5°C to 40°C, with a maximum average temperature of +35°C over 24 hours | ||

| Relative humidity | Not exceeding 50% at the highest temperature of +40°C; higher relative humidity is permissible at lower temperatures, e.g., up to 90% at +20°C | |||

| Altitude | ≤ 2000mm(de-rating required for applications above 2000mm) | |||

| Other conditions | Non-dusty environment, no strong impacts or vibrations | |||