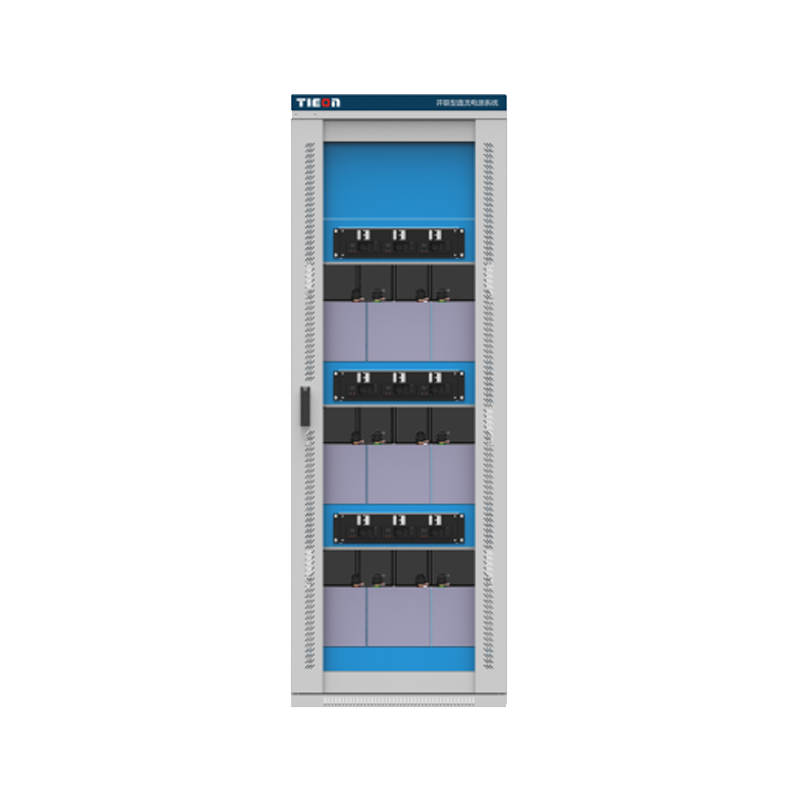

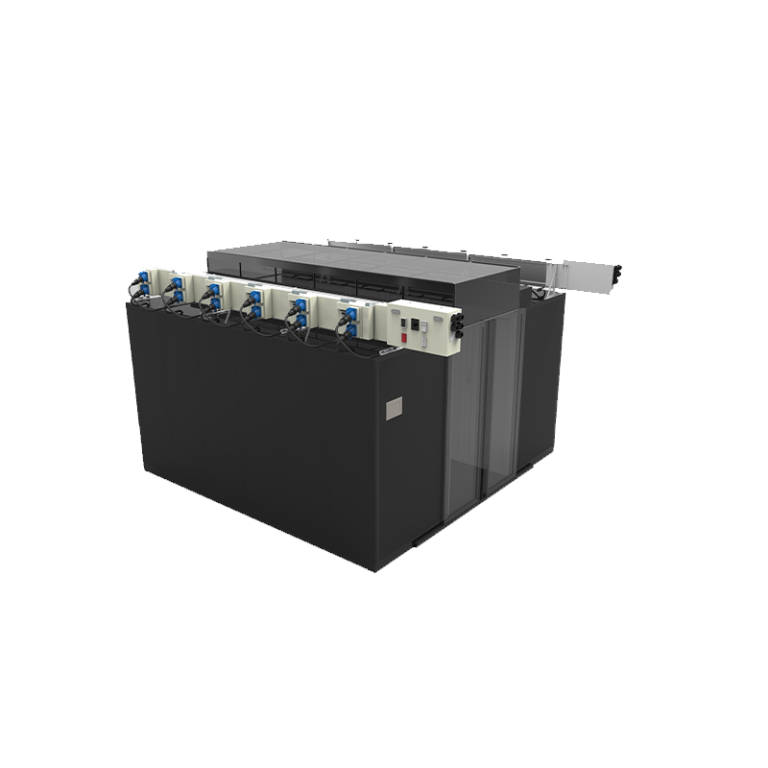

SPC-Line Feeder Module

SPC-Line Feeder Module is designed with standard modularization.The modularized feeder unit integrating circuit breakers, current transformers with smart monitoring modules, primary and secondary circuits, and indicator lights contrasts with conventional feeder branch solutions. The SPCLine smart module solution achieves complete standardization of feeder branches, significantly enhancing monitoring intelligence and operational convenience from all dimensions.

Share to:

Standard Modularization

- SPC-Line Feeder Module is composed of micro circuit breaker unit, monitoring and input/output terminal and base modules, which is suitable for four feeder types of 1P, 2P, 3P and 4P. It is suitable for applications in circuit breaker feeder branch of 63A and below of AC power supply, DC power supply, communication power supply and UPS/INV power supply system.

- It can greatly reduce spare parts and save material costs.

- In the process of operation and maintenance, the fault module can be replaced to effectively improve the operation and maintenance efficiency.

Intelligent Monitoring

- Full power/temperature online monitoring: The feeder branch can collect current,voltage, power, power, harmonics and other full power and temperature data, and has the monitoring function of switching quantity opening and closing/tripping.

- Distributed insulation processing: The insulation monitoring is distributed from the intelligent feeder module to collect and process the insulation data of the whole module on the spot, with no influence between the different modules of the 12 branch circuits.

- Double indicator light configuration: the feeder branch can be configured with double indicator lights, including closing indicator lights and insulation abnormal alarm indicator lights.

- Switching quantity monitoring: with opening and closing/tripping alarm state monitoring;

- Temperature monitoring: with loop inlet temperature monitoring function.

Three-stage Phase Modulation

Support ABC three-stage phase modulation, with phase sequence display function, to help reduce the system imbalance, reduce the zero ground voltage.

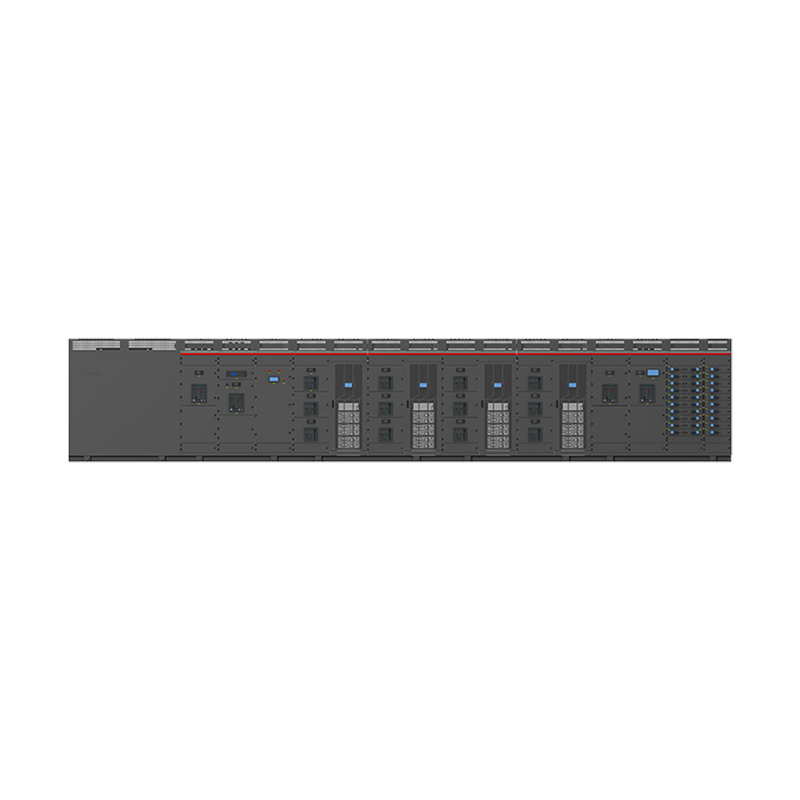

Online Rapid Expansion

The feeder unit adopts the double combination mode of plug-in body + fixed base, which can be expanded and installed online according to the later capacity increase:

- Method Ⅰ: The fixed base part is configured according to the full capacity, and the plug-in body part (including the switch) is reserved for the spare installation position. The plug-in body part must be added for online installation and expansion.

- Method Ⅱ: The fixed base and the plug-in body (including the switch) are reserved for the spare installation position, and two parts each must be installed for expansion.

|

Operating Condition |

Operating temperature | -10℃~60℃ |

| Storage temperature | -25℃~65℃ | |

| Relative humidity | ≤90% (40±2℃) | |

| Power supply input range | ±12Vdc (rated-voltage range ±10Vdc~±15Vdc) | |

| Rated current of primary loop | 63A | |

|

Measuring Range |

DC branch voltage testing range | -5V~5V (-20mA~20mA) |

| Measurement range of DC branch grounding resistance | 0~200K | |

| AC branch voltage testing range | 0V~300V AC | |

| AC branch current testing range | 0~63A AC | |

|

Measuring Accuracy |

DC leakage sensor voltage testing accuracy | 1% |

| DC resistance to ground testing accuracy | 0~50K is ±5%, and 51K~200K is ±10% | |

| The DC branch voltage monitoring is only for reference, which is used to judge the switching state and light the closing indicator light. | ||

| AC voltage and current testing accuracy | 0.5% | |

| AC power electric energy testing accuracy | 0.5% | |

| AC temperature testing accuracy | 1 degree, used to analyze the temperature rise trend at the end of the line. | |