In modern critical infrastructure, DC power supply system plays a vital role in providing stable and reliable power for substations, data centers, rail transit systems, and other key applications.

However, the operational challenges of traditional series DC power systems are increasingly becoming a bottleneck that limits the safe and stable operation of power systems.

With years of power system development and on-site service experience, Tieon Energy has introduced a parallel DC power supply system that fundamentally addresses these issues, ushering in a new era in DC power system maintenance and operations.

(Real-World Scenario: Tieon Product in Substation)

Operational Challenges of Traditional Series DC Power Supply Systems

1. System Reliability Concerns

Traditional series DC power supply system faces significant “weakest link” dilemmas — a failure in any single battery cell can lead to the failure of the entire battery bank, severely impacting system reliability. According to incomplete statistics, up to 83% of DC power system failures are due to battery issues, highlighting the inherent design flaws of traditional systems.

2. Complexity and Cost Pressure in Maintenance

2.1 Cannot Perform Online Maintenance:

Traditional systems do not support online battery replacement, requiring offline operations for each maintenance task.

2.2 Heavy Capacity Verification Workload:

Verifying the capacity of a battery bank requires at least two people working for 2 to 3 days, resulting in high labor costs.

2.3 Difficult Spare Management:

To address potential failures, a large number of spare batteries of the same model must be kept in stock, increasing management complexity.

2.4 High Replacement Costs:

When part of the battery pack fails, the entire group often needs to be replaced, even though most cells may still be functional.

2.5 Significant Power Outage Risks:

Each offline battery maintenance operation poses a risk to the continuous power supply of the DC system.

These issues not only increase the workload of maintenance personnel but also significantly reduce system reliability and economic efficiency, posing potential threats to the safe and stable operation of critical infrastructure.

Core Technological Advantages of Parallel DC Power Supply Systems

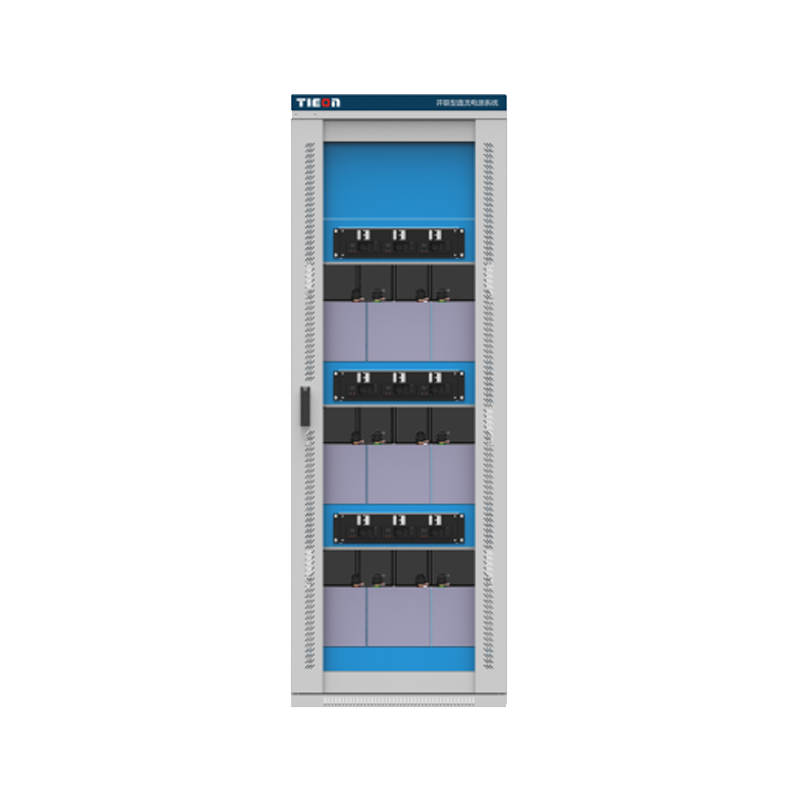

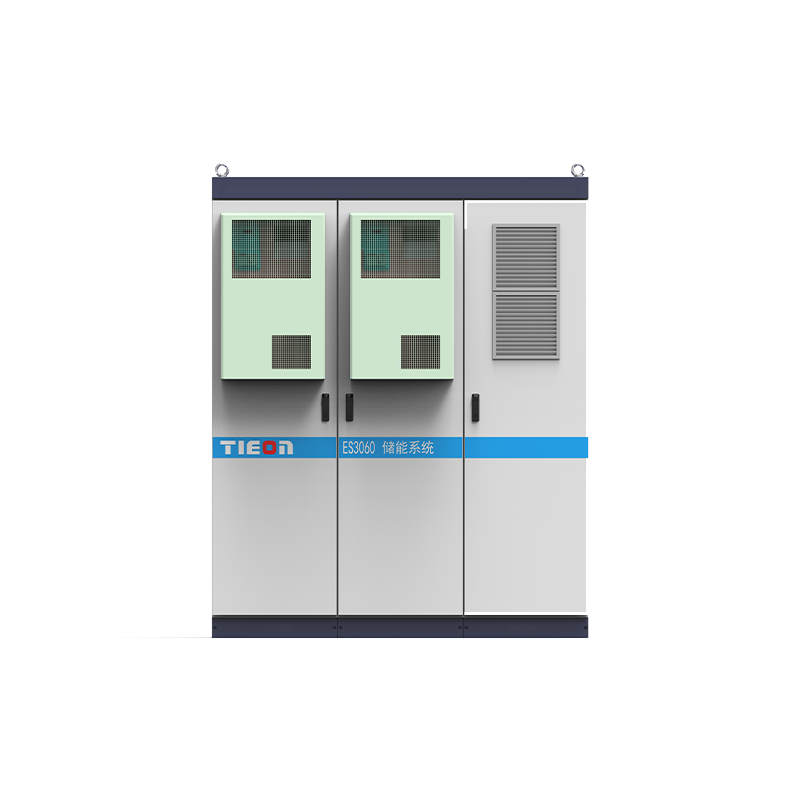

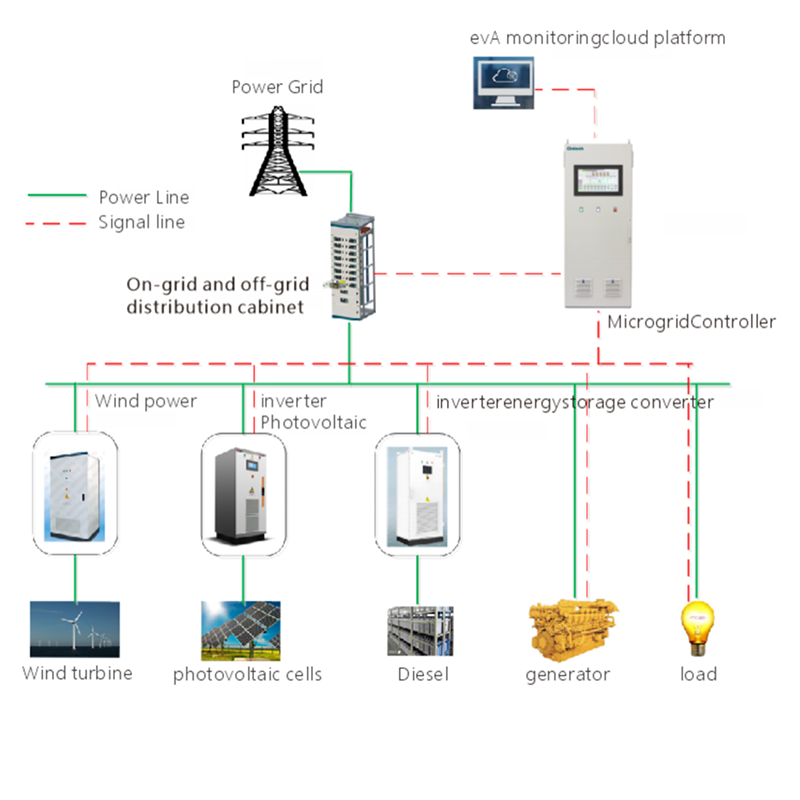

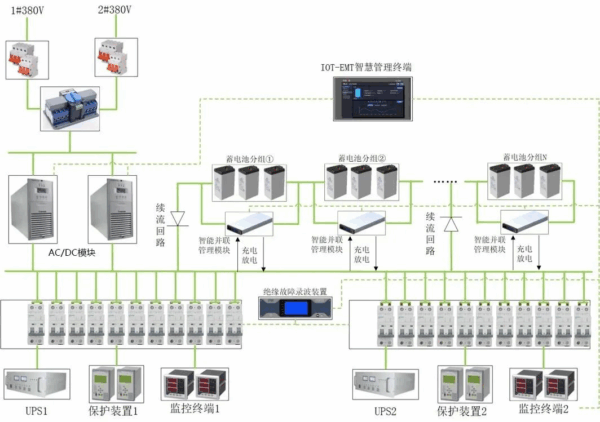

Tieon Energy’s parallel DC power supply system employs an innovative parallel power supply architecture, integrating digital DSP control technology, soft-switching technology, and end-device big data management. This creates a new DC power supply solution. The system consists of AC distribution units, DC distribution units, rectifier units, parallel power modules, monitoring modules, and lightning protection units, forming a multi-tier backup power supply assurance system for DC power.

(Parallel DC Power Supply System Solution Overview)

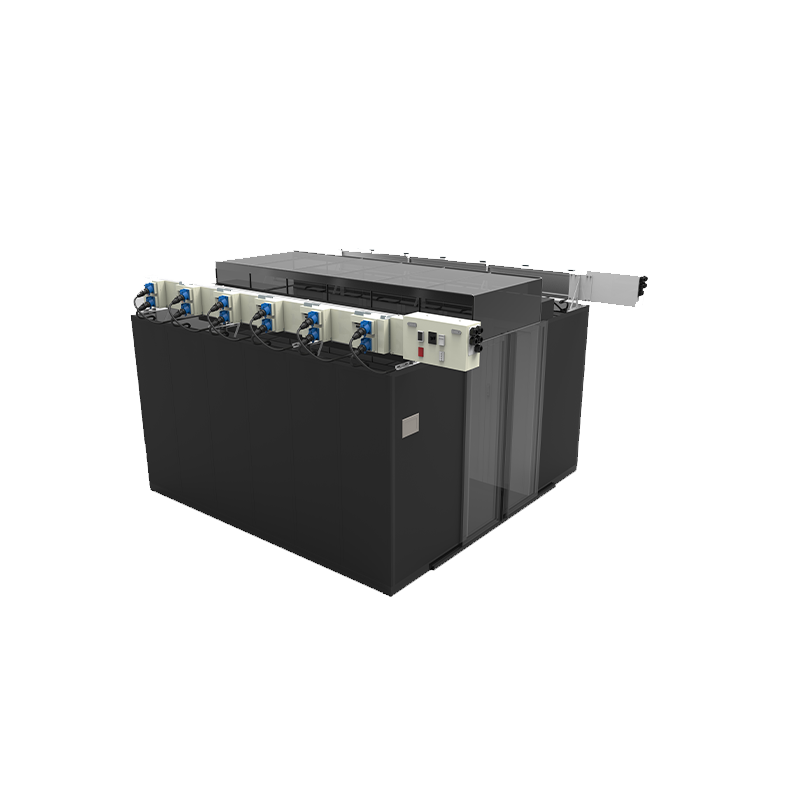

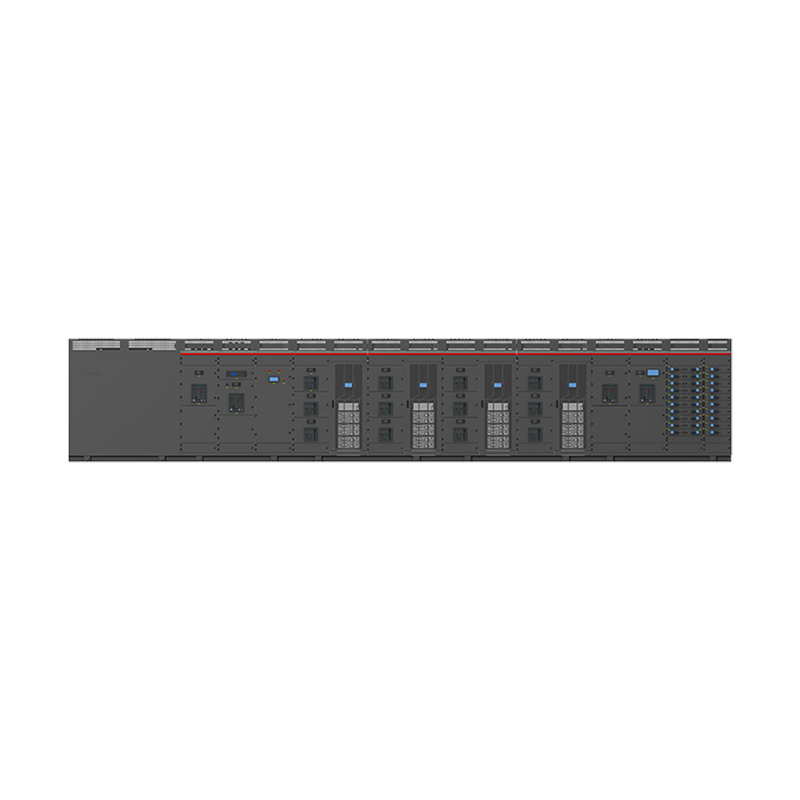

(Application Cases)

TIEON Parallel DC Power Supply System Technical Advantages:

- Parallel Architecture Design:

Eliminates the “weakest link” effect — a failure in a single battery cell does not affect overall system operation.

- Three-Level Power Supply Assurance:

With rectifier modules, parallel modules, and backup batteries providing triple redundancy, system reliability is significantly enhanced.

- Modular Structure:

Parallel module units support partial online maintenance and flexible capacity expansion.

- Intelligent Management Platform:

Integrates big data analytics technology to achieve comprehensive visual management of equipment status.

Comprehensive Overview of the Convenience of Parallel DC Power Supply System Maintenance

1. Online Battery Replacement and Maintenance: Say Goodbye to Power Outage Troubles

The parallel DC power supply system enables online battery replacement and maintenance, bringing revolutionary changes to maintenance work:

1.1 Battery Online Replacement:

A single faulty battery does not affect the entire system’s normal operation, allowing for direct online replacement without power outages.

1.2 Mixed Use of New and Old Batteries:

The system supports the mixed use of batteries from different times, brands, and types, significantly improving battery resource utilization efficiency.

1.3 Enhanced Maintenance Safety:

Avoids the risks associated with power outage operations, enhancing maintenance safety and efficiency.

2. Automatic Capacity Verification: A Leap in Maintenance Efficiency

Traditional series DC power systems have cumbersome and time-consuming capacity verification processes, while parallel systems achieve fully automated capacity verification through intelligent design:

2.1 Automatic Online Capacity Verification:

The system can automatically execute full-capacity verification of batteries without requiring manual on-site operations.

2.2 Smart Report Generation:

After capacity verification, standardized reports are automatically generated, reducing the workload of maintenance personnel.

2.3 Convenient Data Export:

Capacity verification data can be exported via USB interface for easy management and in-depth analysis.

2.4 Significant Cost Savings:

Compared to traditional series systems, it saves labor costs, electricity costs, and time costs.

This function not only significantly reduces labor costs but also improves the accuracy and objectivity of capacity verification through standardized procedures, providing a scientific basis for battery management and making maintenance decisions more precise and efficient.

3. Modular Design: The Smart Choice for Flexible Expansion

The modular design of the parallel DC power supply system brings unprecedented convenience to maintenance work:

3.1 Modular Plug-and-Play Maintenance:

Parallel modules use hot-swappable structures for quick and easy installation and replacement.

3.2 Flexible Capacity Expansion:

The modular parallel power supply design allows system capacity to be increased or decreased, supporting “plug-and-play” expansion to meet varying load demands.

3.3 Standardized Design:

The system can adopt unified standard designs to simplify installation processes, lower technical barriers, and improve maintenance efficiency.

3.4 Flexible Power Supply Arrangement:

Supports both distributed and centralized DC power supply arrangements, allowing selection based on demand.

Modular design not only simplifies daily maintenance but also provides significant convenience for system upgrades and capacity expansion, enabling power systems to flexibly respond to changing power needs.

4. Intelligent Management System: A New Digital Maintenance Experience

The parallel DC power supply system is equipped with advanced intelligent management systems, providing comprehensive support for maintenance work:

4.1 Full-View Equipment Status Monitoring:

The system monitoring interface displays rich information comprehensively, making the equipment status clear at a glance, both locally and remotely.

4.2 Big Data Processing Capability:

Large-capacity data storage with comparative analysis of new and old data improves intelligent fault analysis and diagnosis.

4.3 Smart Charging and Discharging Management:

The system intelligently manages battery groups, controlling charging and discharging autonomously, with real-time controllable operational status.

4.4 Customizable Capacity Verification Plans:

Capacity verification supports setting multiple management plans, adjustable as needed, allowing for refined management based on battery characteristics and operational conditions.

Through these intelligent functions, the parallel DC power supply system transitions maintenance work from “reactive response” to “proactive prevention.” Maintenance personnel can remotely monitor system status, promptly identify potential issues, and take preventive measures, significantly reducing the frequency and workload of on-site inspections.

5. Multi-Dimensional Battery Management: Precise Control Over Battery Lifecycle

The parallel DC power supply system employs multi-dimensional battery management technology to achieve comprehensive intelligent monitoring of batteries:

5.1 Real-Time Multi-Parameter Monitoring:

The system continuously collects key parameters such as voltage, internal resistance, and temperature for each individual battery.

5.2 Self-Analysis of Health Status:

Analyzes battery health status using various strategies, assessing performance consistency, and promptly alarms when detecting deteriorating batteries.

5.3 Periodic Internal Resistance Testing:

Can preset battery internal resistance testing cycles or trigger conditions for automatic initiation of internal resistance testing.

This function transforms battery management from the traditional “failure replacement” model to a “predictive maintenance” model, improving system reliability and battery usage efficiency.

(Maintenance Scenarios)

Embarking on a New Journey Toward Intelligent Maintenance

With the deepening development of smart grids and digital transformation, the future of DC power supply system lies in intelligence and networking. TIEON’s parallel DC power supply system is already leading this trend. Through innovative technical design and intelligent management, it has fundamentally resolved the operational and maintenance challenges of traditional series systems, offering users a DC power solution that features high reliability, efficient maintenance, smart management, and environmental sustainability.

Looking ahead, TIEON will continue to uphold its corporate vision — “Making Power Usage More Worry-Free” — and drive forward technological innovation by focusing on the following key areas:

Intelligent Predictive Technologies

Continuously optimizing fault prediction algorithms to further enhance system reliability.

Cloud-Edge Collaborative Management

Building a cloud-based management platform to enable coordinated operations across multiple sites.

Energy Efficiency Optimization

Further improving system efficiency to reduce operating costs.

Green and Environmentally Friendly Design

Reducing resource consumption and extending equipment service life.

Join TIEON in Building a Smarter Power Future

TIEON’s parallel DC power supply system, with its exceptional maintenance convenience and significant economic benefits, is redefining the standards for DC power system operations. We believe that as technology continues to advance and applications expand, parallel DC power supply systems will play an increasingly important role across broader fields, providing more reliable support for the safe and stable operation of power systems.