In the daily management of electrical systems, insulation monitoring is a key link to ensure the safe operation of electrical equipment. It can not only reveal potential safety hazards in a timely manner, but also provide an important basis for the maintenance of electrical equipment. This article will take you to a deep understanding of the purpose and methods of insulation monitoring.

1. The principle of DC insulation recording

The DC insulation recording technology uses high-precision sensors to collect voltage, current and other signals in the DC system in real time, and uses advanced digital signal processing technology to analyze and process these signals, thereby realizing the monitoring and recording of the DC insulation status. This technology can capture and save the weak signals generated by the insulation material when an abnormality occurs, which is useful for subsequent fault analysis. and processing.

2. Function of DC insulation recording

Real-time monitoring: The DC insulation recording system can monitor the insulation status of the DC system in real time and continuously, ensuring early detection and early processing of potential safety hazards.

Data recording: The system can automatically record the changes in the insulation status, including the changing trends of key parameters such as voltage and current, and provide data support for subsequent fault analysis.

Intelligent analysis: Through the built-in intelligent algorithm, the system can automatically analyze the monitored data, identify potential insulation faults, and give corresponding processing suggestions.

Alarm prompt: When the system detects insulation abnormality, it will Immediately trigger the alarm prompt to ensure that the operation and maintenance personnel can take timely measures to deal with it.

3. Application value of DC insulation recording

The application value of DC insulation recording technology in power systems is mainly reflected in the following aspects:

Improve equipment reliability: By real-time monitoring and recording of DC insulation status, potential insulation faults can be discovered and handled in time to improve the reliability and stability of equipment.

Reduce operation and maintenance costs: Through intelligent analysis and alarm prompt functions, the workload and misjudgment rate of operation and maintenance personnel can be reduced, and the operation and maintenance costs can be reduced.

Optimize system operation: Through continuous monitoring and analysis of DC insulation status, system operation parameters can be optimized and system The operating efficiency and safety of the system.

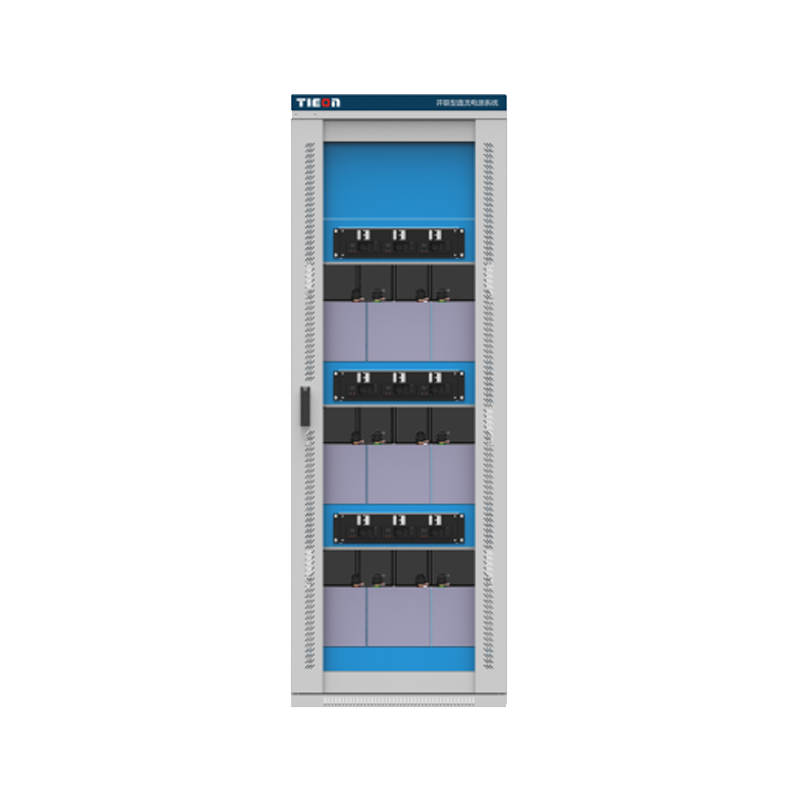

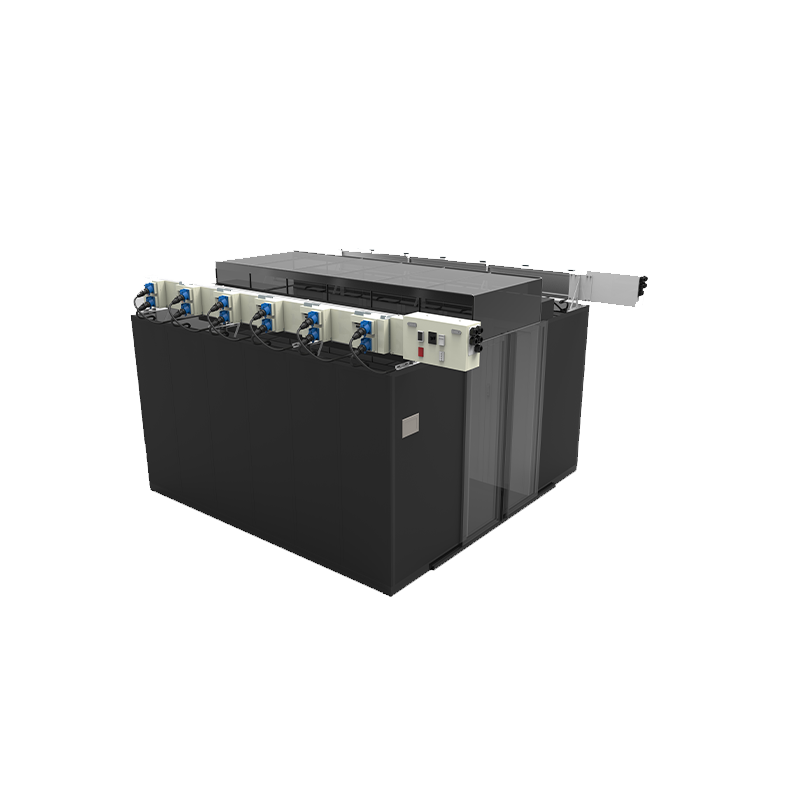

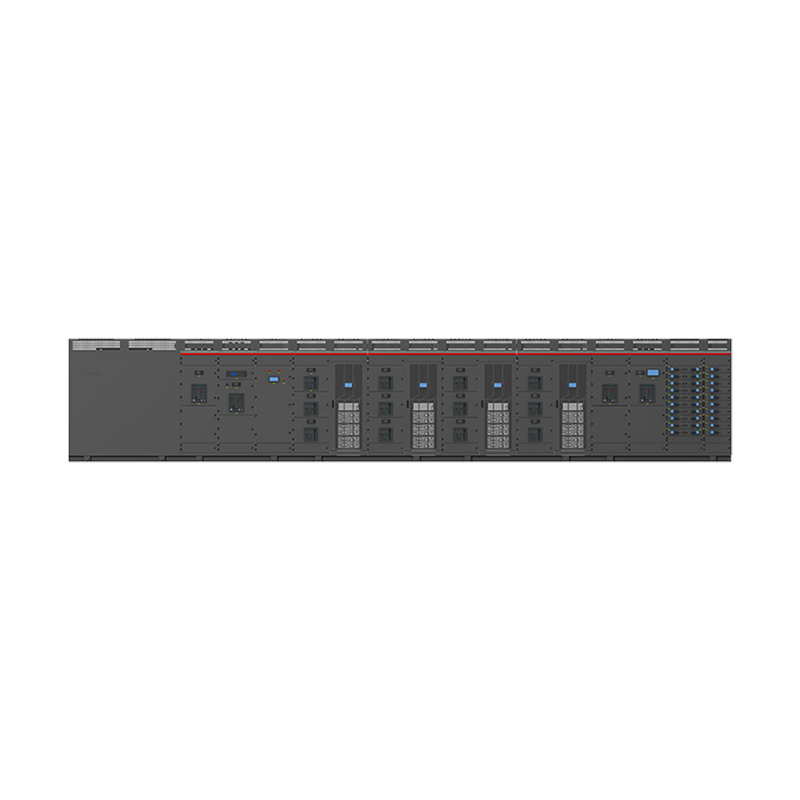

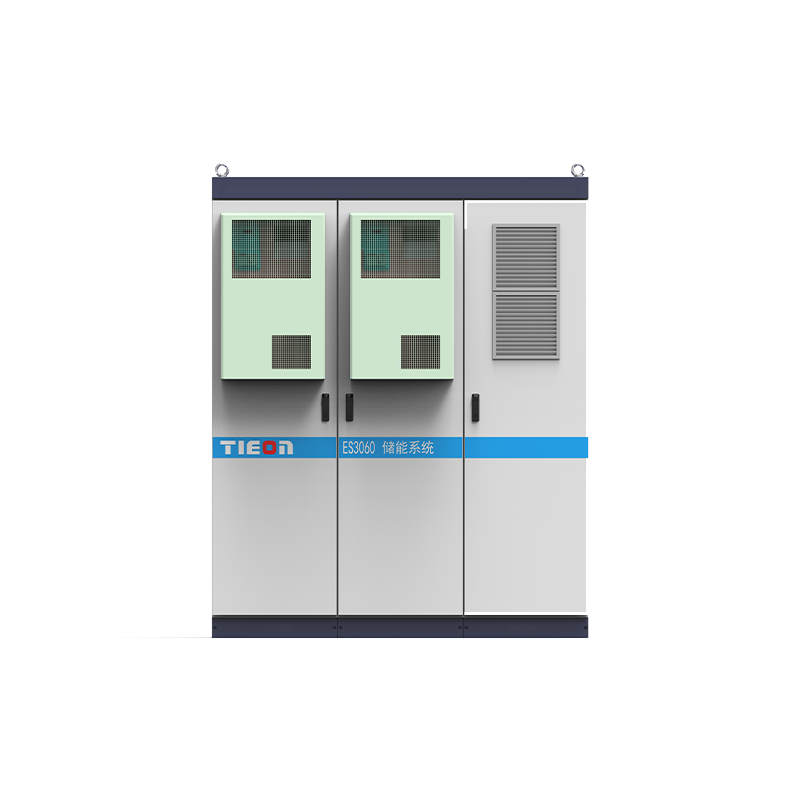

4.Tieon Energy’s DC insulation recording solution

As a leading enterprise in the field of power technology, Tieon Energy has been committed to providing customers with efficient and reliable DC insulation recording solutions. Tieon Energy’s DC insulation recording system adopts advanced technology and algorithms, with the characteristics of high precision, high reliability, and easy operation. At the same time, Tieon Energy also provides professional technical support and after-sales service to ensure that customers get timely and effective help during use.

In short, DC insulation recording technology is one of the important means to ensure the safe operation of the power system. Choosing Tieon Energy’s DC insulation recording solution will provide solid protection for your power system.